Earlsdon

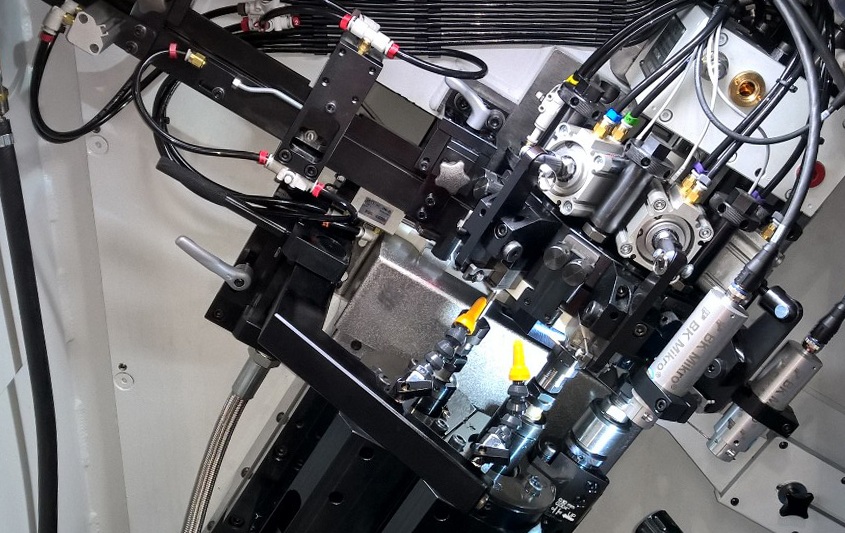

ADB-X4

Automatic Drill Point and Broach Machine

Key Points

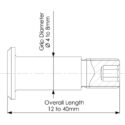

- Drilling, Pointing, Facing and Broaching of Aerospace Fasteners

- A fast, flexible, reliable machine specially designed for the job

- 800 – 1400 parts per hour depending on size

- Fast changeover

- Safe, clean working and easy maintenance

- >60 e-tech Drill / Broach machines running on customers’

sites - Specially-written user-friendly software in multiple languages

- Industry 4.0 compatible

Machine Features

- 18” dia Vibratory Bowl Feeder

- Indexing Disk with locations to suit 5 different diameters

(Indexing Disks can easily be changed) - 5 stations: Load, Center Drill / Point & Face, Drill, Broach & Unload

- 2 Rotating spindles with independent variable speed up to 6000rpm

- Hydraulic Feed-rate Control

- Quick-change pre-settable tooling

- Allen Bradley or Siemens PLC control system with

6” touch-screen (HMI) - Automatic tool breakage detectors

Got an enquiry?

Fill in our form and we’ll get back to you as soon as possible.

Give us a call

on +44 (0) 24 7671 7023 and speak to our friendly support team.

Support & Spares

We will give you all of the assistance you need with maintenance, support and spares.