Earlsdon

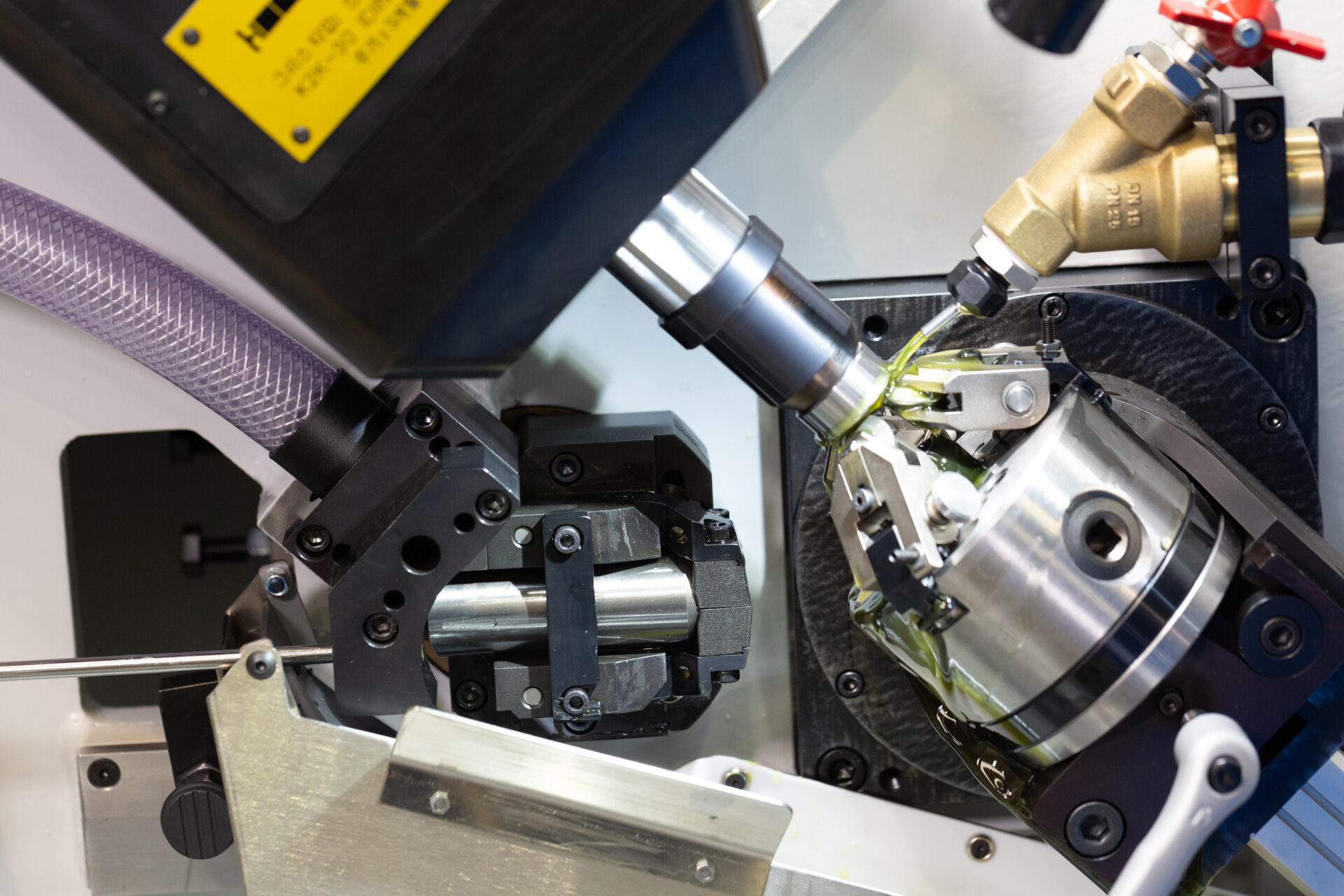

FR-FX5

Flexible Automatic Fillet Rolling Machine

Key Points

- Rolling the underhead radius

- 800 – 1500 parts per hour depending on size

- Precise, programmable rolling parameters with 100% in-process checking.

- Fast changeover

- Safe, clean working and easy maintenance

- Specially-written user-friendly software in multiple languages

- 3G / Ethernet Modem for remote access

- Industry 4.0 compatible

Machine Features

- Load cell to measure actual rolling force during each cycle and to check that it is within programmed limits

- Programmable control of rolling force, rpm & rolling time

- Pneumatic cylinder producing up to 1,000kg rolling force

- Drive unit with inverter controlled spindle motor

- 18” dia (450 mm) Vibratory Bowl Feeder

- ‘Air-mover’ system to deliver parts into machine

- Fast pneumatically-actuated loading system

- 12” colour touch-screen (HMI)

- Integrated coolant tank, filter and pump

Got an enquiry?

Fill in our form and we’ll get back to you as soon as possible.

Give us a call

on +44 (0) 24 7671 7023 and speak to our friendly support team.

Support & Spares

We will give you all of the assistance you need with maintenance, support and spares.